Purlin Roll Forming Machine Manufacturers

Product Overview

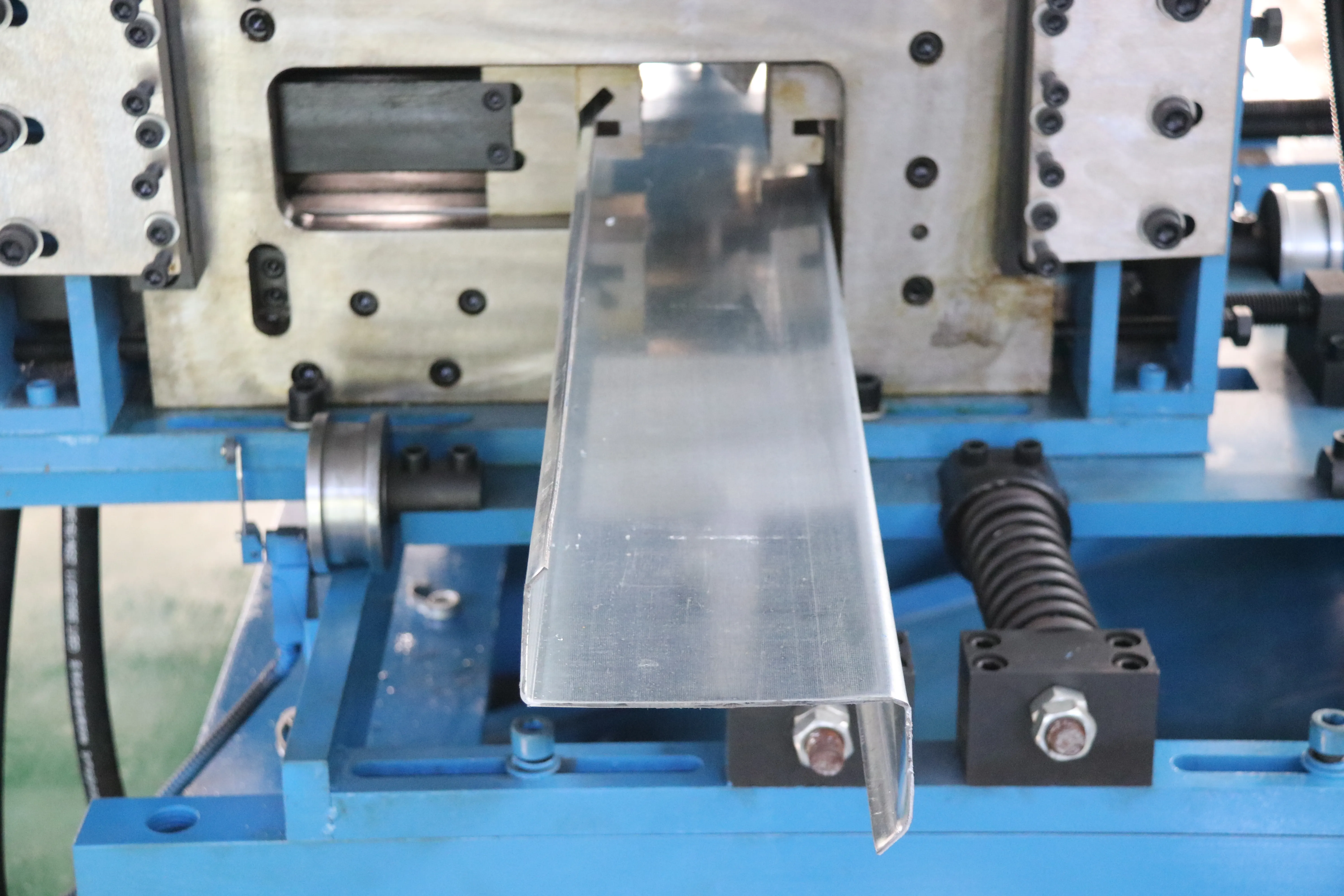

- The purlin roll forming machine is used in the steel construction industry to produce C-shaped and Z-shaped purlins for supporting roof decking and roofing sheets.

Product Features

- The machine can produce purlins of various sizes and thicknesses, and can automatically change profiles and specifications.

- It is equipped with components such as a decoiler, punching unit, sheet leveling unit, sheet guiding equipment, roll forming section, and PLC control system.

- The machine is highly adjustable, capable of producing a variety of cross-sections, saving time and money for users.

- It can produce purlins at a fast pace and is popular among steel structure manufacturers.

- Purlin size change and CZ interchange are controlled by PLC and touch panel, allowing for quick adjustments.

Product Value

- The machine provides efficient and cost-effective production of C and Z-shaped purlins, saving time and money for users.

- It offers high precision and versatility in producing purlins of various sizes and specifications.

- The machine is easy to operate and maintain, ensuring smooth production processes for steel construction projects.

Product Advantages

- Ability to produce both C-shaped and Z-shaped purlins of various sizes and thicknesses.

- Automatic profile and specification changes, saving time and effort for users.

- Sturdy body frame and high adjustability for versatile production capabilities.

- Fast production pace and ability to produce a variety of cross-sections.

- Precision control of purlin size changes and CZ interchange for efficient operation.

Application Scenarios

- The purlin roll forming machine is ideal for steel construction projects requiring C and Z-shaped purlins for roof decking and roofing sheets.

- It is suitable for use in manufacturing facilities, construction sites, and steel structure manufacturing plants.

- The machine can be used in various industries such as construction, architecture, and metal fabrication for producing high-quality purlins.

HAIXING