HAIXING - Professional Cold Roll Forming Machine Manufacturer

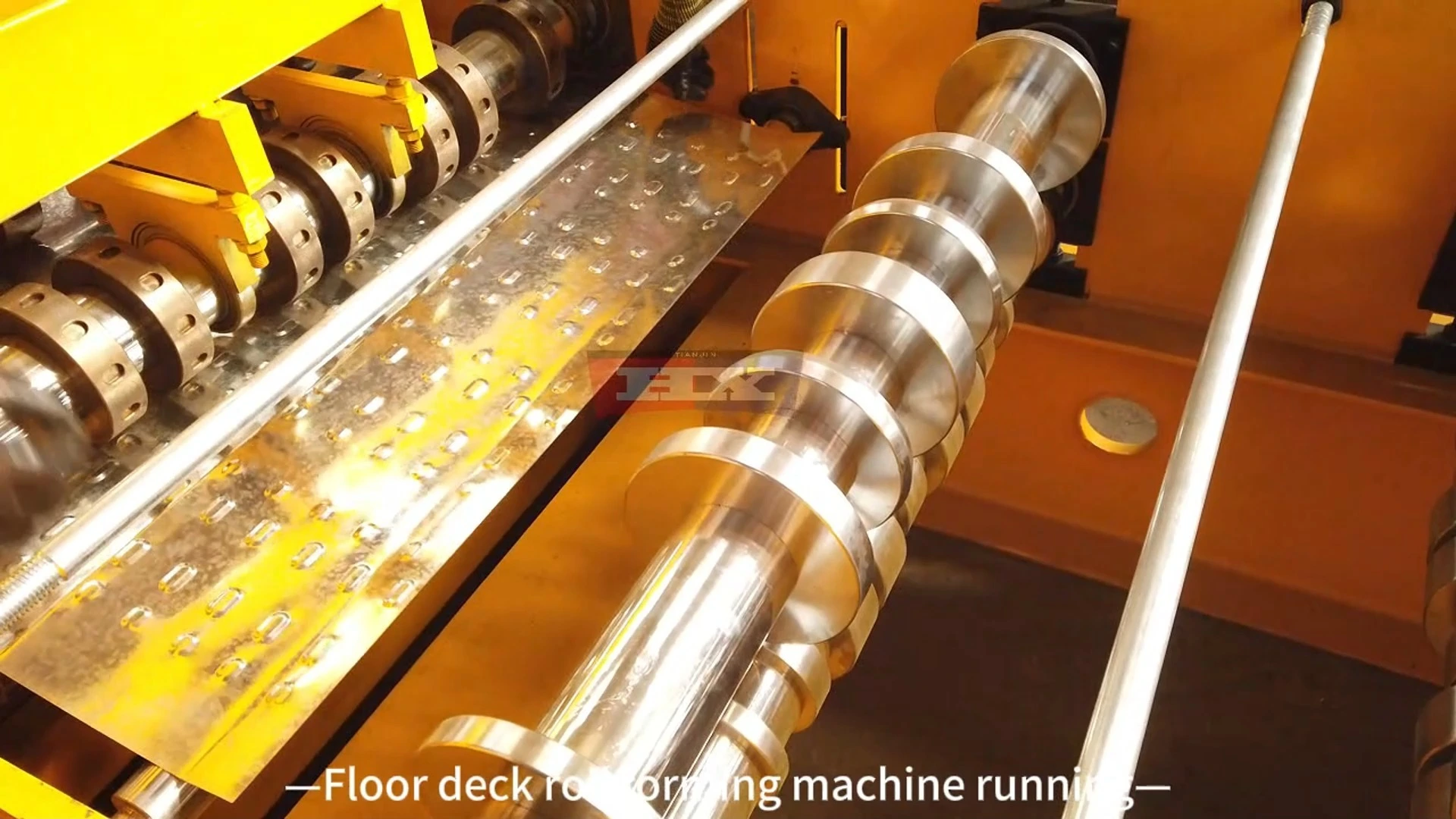

Galvanized Floor Deck Sheet Tile Panel Roll Forming Machine Making Machine

Dimensions: 6700*1500*1800mm

Voltage: 380V

Productivity: 8-15m/min

Weight: 8.5 ton

Warranty: 2 years

Rolling thinckness: 0.7-1.5mm

Feeding width: 1220mm

Control system: PLC(imported Brand)

Cutting blade material: Cr 12 Steel

Shaft material: 45# Steel

Suitable to process: Galvanized coils

Usage: Construction

Galvanized Floor Deck Sheet Tile Panel Roll Forming Machine Making Machine Product description

Our Galvanized Floor Deck Sheet Tile Panel Roll Forming Machine Making Machine is specially engineered for producing high-strength floor decking panels widely used in multi-story steel structure buildings. These deck panels serve as a permanent formwork and provide excellent load-bearing capacity and composite action with concrete slabs.

The machine ensures precise forming of profiles with optional embossing to improve slip resistance and concrete bonding.

Raw Material: Galvanized Steel (GI), Galvalume (GL)

Material Thickness: 0.8 – 1.5 mm (optional up to 2.0 mm)

Effective Width: 600 – 1000 mm (customizable)

Forming Speed: 10 – 15 m/min

Roller Stations: 20 – 32 stations (depends on profile)

Roller Material: GCr15 steel, heat-treated & chrome coated

Drive System: Chain or Gearbox drive

Cutting System: Hydraulic cutting with PLC length control

Control System: PLC automatic system with HMI screen (Siemens/Delta)

Embossing System: Optional (roller or hydraulic type)

our customers

Product packaging