Unveiling The Efficiency Of Roof Roll Forming Machines: A Revolution In Construction Technology

Are you curious about the latest advancements in construction technology? Look no further than the efficiency of roof roll forming machines. This innovative technology is revolutionizing the way roofs are constructed, offering faster production times and higher levels of precision. In this article, we will delve into the game-changing impact of roof roll forming machines and how they are shaping the future of construction. Whether you’re a building professional or simply interested in cutting-edge technology, this is a must-read.

- Understanding the Impact of Roof Roll Forming Machines on Construction Efficiency

Roof roll forming machines have revolutionized the construction industry by significantly improving efficiency, speed, and accuracy in the production of roofing materials. These machines have had a profound impact on construction efficiency, and understanding their benefits is crucial for anyone involved in the construction or roofing industry.

One of the most significant advantages of roof roll forming machines is their ability to streamline the production process. Traditional methods of producing roof materials involved multiple steps and tools, leading to increased labor costs and longer production times. However, with the introduction of roof roll forming machines, this process has been simplified, with the ability to produce custom lengths and designs on-site. This has led to a significant reduction in material waste and an increase in overall efficiency.

In addition to streamlining the production process, roof roll forming machines also contribute to a significant increase in construction speed. By producing materials on-site and in a timely manner, construction projects can be completed more quickly, saving time and money. Furthermore, the ability to create custom lengths and designs ensures that materials fit perfectly, eliminating the need for time-consuming adjustments or corrections.

Another key benefit of roof roll forming machines is their ability to produce high-quality and consistent roofing materials. With precise measurements and automated processes, the risk of errors and defects is significantly reduced, leading to a higher quality end product. This not only improves the overall appearance of the finished construction but also contributes to its long-term durability and performance.

Furthermore, the use of roof roll forming machines has also had a positive impact on labor costs. By reducing the need for manual labor and minimizing the risk of errors, construction companies can save on labor expenses and allocate resources more effectively. This not only benefits the companies themselves but also contributes to overall cost savings for construction projects.

From an environmental perspective, the use of roof roll forming machines has also been beneficial. By minimizing material waste and reducing the need for transportation, these machines contribute to a more sustainable approach to construction. This is particularly important as the construction industry seeks to minimize its environmental impact and embrace more eco-friendly practices.

In conclusion, the impact of roof roll forming machines on construction efficiency cannot be understated. These machines have revolutionized the production of roofing materials, leading to increased speed, accuracy, and cost savings. Their ability to streamline the production process, increase construction speed, improve quality, reduce labor costs, and promote sustainability makes them an invaluable asset to the construction industry. As technology continues to advance, it is likely that the use of roof roll forming machines will only continue to grow, further revolutionizing the way construction projects are carried out.

- Innovations in Roof Roll Forming Technology

Innovations in Roof Roll Forming Technology

Roof roll forming machines have long been an integral part of the construction industry, but in recent years, there has been a revolution in the technology that has made them even more efficient and effective. These innovations have led to significant improvements in the way roofs are manufactured, resulting in faster production times, higher quality products, and ultimately, a more streamlined construction process.

One of the most significant developments in roof roll forming technology is the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These systems allow for precise and automated control of the forming process, resulting in more consistent and accurate roof profiles. This level of precision has not only enhanced the quality of the finished product but has also reduced material waste, thereby contributing to a more sustainable and cost-effective manufacturing process.

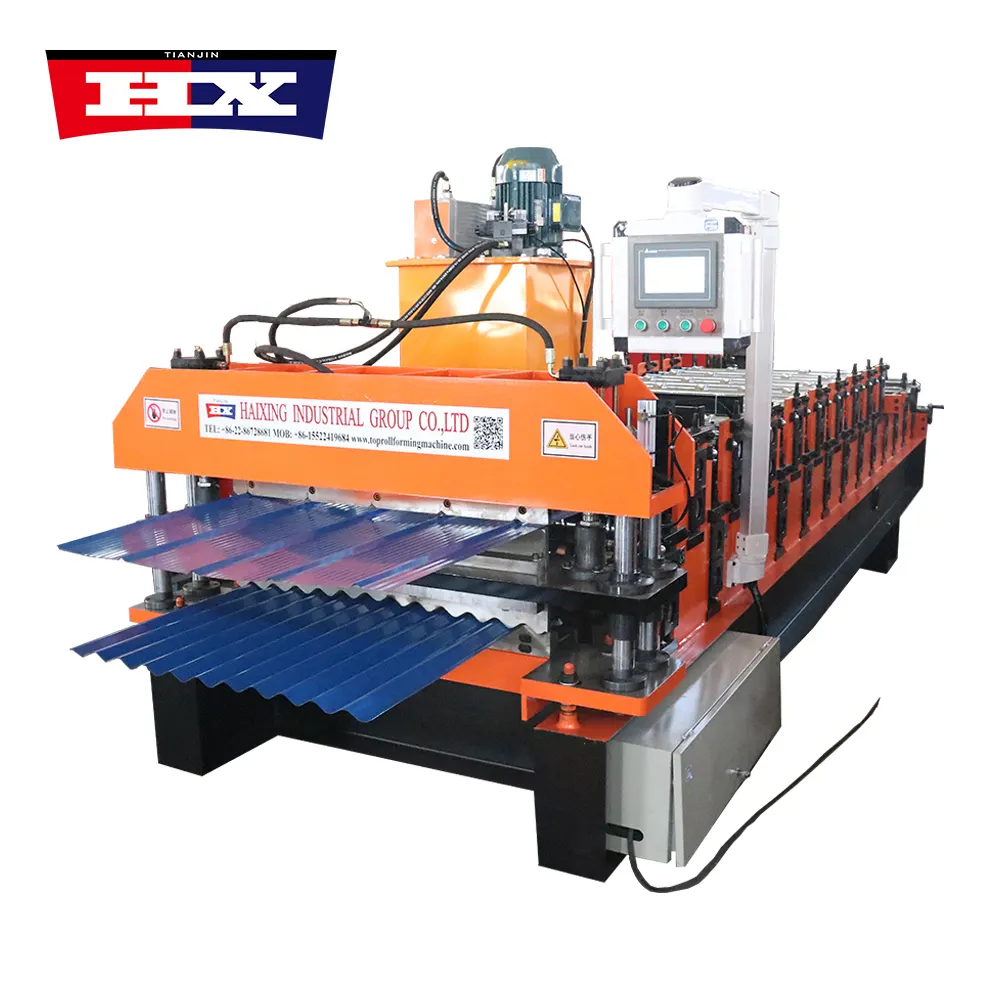

Another innovation that has revolutionized roof roll forming technology is the introduction of advanced roll forming machines that are capable of producing a wider range of roof profiles. These modern machines are equipped with multiple sets of rollers and cutting tools, allowing for the production of complex and custom designs that were previously difficult or impractical to achieve. This versatility has expanded the possibilities for architects and builders, enabling them to create unique and aesthetically appealing roof designs that were once thought to be unattainable.

Furthermore, advancements in material handling and feeding systems have significantly increased the speed and efficiency of roof roll forming machines. Improved coil handling systems and in-line punching and embossing equipment have minimized downtime and increased the overall productivity of the machines. This has not only reduced production costs but has also enabled manufacturers to meet tight deadlines and respond to the demands of the market more swiftly.

In addition to these technological advancements, the incorporation of energy-efficient components and systems in roof roll forming machines has contributed to a decrease in energy consumption and overall environmental impact. By utilizing energy-efficient motors, advanced lubrication systems, and optimized control algorithms, the new generation of roll forming machines offers a more sustainable and eco-friendly manufacturing solution for the construction industry.

Overall, the innovations in roof roll forming technology have transformed the way roofs are manufactured and have set a new standard for efficiency and quality in the construction industry. With the integration of CAD/CAM systems, versatile roll forming machines, advanced material handling systems, and energy-efficient components, the future of roof manufacturing looks promising. These advancements not only benefit manufacturers and construction companies by improving productivity and reducing costs but also contribute to the creation of more durable and visually appealing buildings. As the demand for innovative and sustainable construction solutions continues to grow, the evolution of roof roll forming technology will undoubtedly play a crucial role in shaping the future of the industry.

- Advantages of Using Roof Roll Forming Machines in Construction

Roof roll forming machines have completely revolutionized the construction industry, offering a multitude of advantages that have made them an indispensable tool for roofing projects. These sophisticated machines have redefined the process of creating roof panels, making it faster, more efficient, and cost-effective. In this article, we will delve into the numerous advantages of using roof roll forming machines in construction, shedding light on how they have become an integral part of modern building techniques.

One of the most prominent advantages of using roof roll forming machines is their ability to produce customized and precise roof panels. These machines are equipped with advanced technology that allows for the precise shaping and forming of metal sheets into customized profiles and dimensions according to the specific requirements of the project. This level of precision and customization ensures that the roof panels fit perfectly, eliminating the need for extensive modifications and adjustments. As a result, construction timelines are significantly reduced, and the overall efficiency of the project is greatly enhanced.

Additionally, roof roll forming machines offer unparalleled efficiency in the production of roof panels. These machines are capable of producing a high volume of panels in a relatively short period, effectively streamlining the manufacturing process. This increased efficiency not only reduces labor costs but also minimizes the material waste, making the entire production process more sustainable and cost-effective. Furthermore, the speed and consistency of the production process ensure that projects are completed within tight deadlines, allowing for quicker project turnover and client satisfaction.

Another significant advantage of using roof roll forming machines is their versatility in handling a wide range of materials. These machines can work with various metal sheets, including steel, aluminum, and copper, offering flexibility in design and material choices for roofing projects. This versatility allows for the creation of durable and long-lasting roof panels that can withstand harsh weather conditions and environmental elements, ensuring the longevity and structural integrity of the building.

Moreover, roof roll forming machines are designed with ergonomic features that prioritize the safety and well-being of the operators. These machines are equipped with safety guards, sensors, and automated controls that minimize the risk of accidents and injuries during the production process. Additionally, the automated nature of these machines reduces the physical strain on workers, creating a more ergonomically sound working environment.

In conclusion, the advantages of using roof roll forming machines in construction are undeniable. From their ability to produce precise and customized roof panels to their unmatched efficiency and versatility, these machines have truly revolutionized the way roofing projects are executed. As the demand for sustainable and cost-effective building solutions continues to rise, roof roll forming machines have emerged as a game-changer in the construction industry, offering unprecedented value and efficiency to builders, contractors, and developers. As technology continues to evolve, it is expected that roof roll forming machines will continue to play a pivotal role in shaping the future of construction.

- How Roof Roll Forming Machines are Revolutionizing the Construction Industry

Roof roll forming machines have become a game-changer in the construction industry, revolutionizing the way roofs are fabricated and installed. These machines are redefining efficiency, precision, and productivity in the construction of roofs, making them an indispensable tool for roofing contractors and manufacturers.

One of the key features that make roof roll forming machines so revolutionary is their ability to produce consistent and high-quality metal roofing panels. Traditional methods of fabricating roofing panels involve cutting and shaping metal sheets manually, which often results in inconsistencies and inefficiencies. With roof roll forming machines, these issues are a thing of the past. These machines utilize advanced technology to roll and shape metal sheets into precise and uniform roofing panels, ensuring that every panel produced is of the highest quality.

Furthermore, roof roll forming machines are capable of producing roofing panels at an incredibly high speed. This means that manufacturers and contractors can significantly reduce their production time, allowing them to take on more projects and meet tight deadlines. In addition, the speed of these machines also translates to cost savings, as less labor and time are required to produce roofing panels.

Another advantage of roof roll forming machines is their versatility. These machines can be customized to produce a wide variety of roofing panel profiles, allowing for endless design possibilities. Whether it's a standing seam, corrugated, or ribbed panel, these machines can handle it all. This versatility not only gives contractors and manufacturers the freedom to cater to diverse customer needs but also enables them to stay competitive in the market.

In terms of precision, roof roll forming machines excel in delivering accurate and uniform roofing panels. The automation of the forming process eliminates human error, ensuring that each panel produced meets the exact specifications and measurements. This level of precision is crucial in the construction industry, as it guarantees a seamless and secure fit during installation, ultimately leading to a longer-lasting and more reliable roof.

Additionally, the use of roof roll forming machines contributes to environmental sustainability. These machines produce minimal waste, as they are designed to optimize material usage and reduce scrap. This not only helps to lower material costs but also minimizes the environmental impact of the manufacturing process. As the construction industry continues to prioritize sustainable practices, the efficiency and eco-friendliness of roof roll forming machines make them an attractive option for contractors and manufacturers.

In conclusion, roof roll forming machines have undoubtedly revolutionized the construction industry by streamlining the fabrication and installation of high-quality roofing panels. Their efficiency, precision, versatility, and sustainability make them an essential tool for any roofing project. As technology continues to advance, it's safe to say that roof roll forming machines will continue to play a pivotal role in shaping the future of construction.

- The Future of Roof Roll Forming Machines: Transforming Construction Technology

The Future of Roof Roll Forming Machines: Transforming Construction Technology

Roof roll forming machines have been making waves in the construction industry with their revolutionary technology and efficient performance. These machines are transforming the way roofs are manufactured, providing a faster and more cost-effective solution for construction projects. With their ability to produce high-quality roofing materials in a fraction of the time it takes traditional methods, these machines are paving the way for the future of construction technology.

One of the key advantages of roof roll forming machines is their ability to streamline the manufacturing process. Traditional methods of producing roofing materials involve multiple steps and can be time-consuming. However, with a roof roll forming machine, the process is automated, reducing the need for manual labor and increasing efficiency. This not only saves time, but also reduces the overall cost of production, making it a more cost-effective solution for construction companies.

In addition to their efficiency, roof roll forming machines also offer a high level of precision and customization. These machines are able to produce roofing materials to exact specifications, ensuring a perfect fit for any construction project. This level of precision not only improves the overall quality of the roofing materials, but also reduces waste and minimizes the need for rework, saving both time and money for construction companies.

Furthermore, roof roll forming machines are also eco-friendly, making them an attractive option for environmentally conscious construction companies. By reducing the need for excessive material usage and minimizing waste, these machines have a much lower environmental impact compared to traditional manufacturing methods. This not only benefits the environment, but also aligns with the growing demand for sustainable construction practices.

With the construction industry continuously evolving, the future of roof roll forming machines looks promising. As technology continues to advance, these machines are likely to become even more efficient and versatile, further revolutionizing the way roofs are manufactured. In the coming years, we can expect to see even more advanced features, increased automation, and enhanced customization options, making roof roll forming machines an indispensable tool for construction companies.

In conclusion, roof roll forming machines are revolutionizing construction technology by offering a faster, more efficient, and cost-effective solution for manufacturing roofing materials. With their ability to streamline the production process, provide precision and customization, and reduce environmental impact, these machines are set to play a crucial role in the future of construction. As technology continues to advance, we can expect to see even more innovative features and capabilities, further solidifying the position of roof roll forming machines as a game-changer in the construction industry.

Conclusion

In conclusion, the efficiency of roof roll forming machines has indeed brought about a revolution in construction technology. With 11 years of experience in the industry, we have seen firsthand the impact of these machines on the speed, accuracy, and cost-effectiveness of construction projects. The versatility and precision of these machines have enabled us to meet and exceed the expectations of our clients, while also improving our productivity and profitability. As we continue to embrace and harness the power of roof roll forming machines, we are excited to see how they will continue to shape the future of the construction industry. Their efficiency is truly a game-changer, and we look forward to the innovative possibilities that lie ahead.

HAIXING