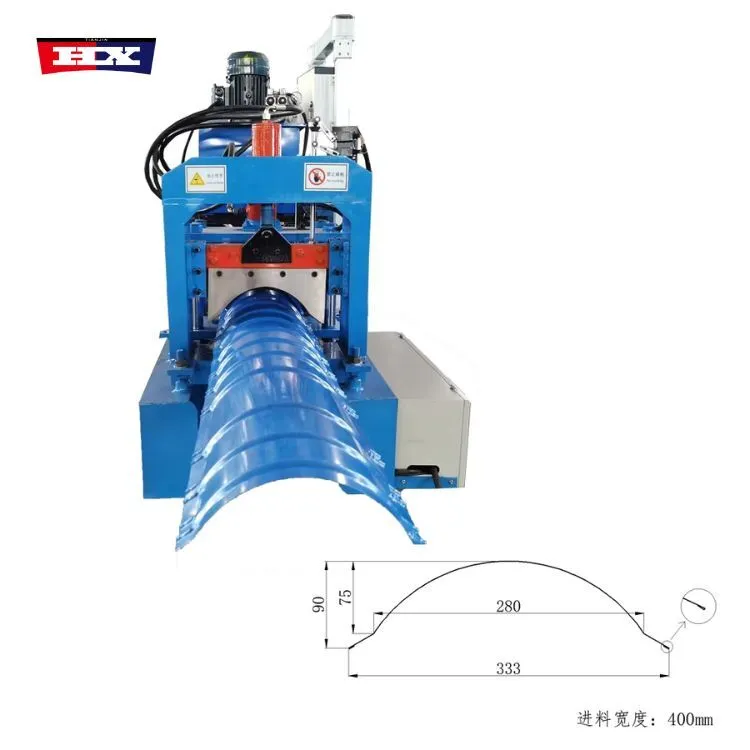

Roof ridge cap roll forming machine1

Product Type: capping roll forming machine

Formed Material: GI/GL, PPGI/PPGL

Material Thickness: 0.3-0.8mm

Material Width: 330mm(customized)

Voltage: 380V 50Hz 3Phase

Forming Speed: 10-15m/min

Decoiler: Manual decoiler (will give you as free)

Product Description

Our roof ridge cap roll forming machine roll forming machine price is specially designed for manufacturing metal ridge caps, which are essential components used to cover the joint at the top of pitched roofs. These caps ensure water-tight sealing, wind protection, and an aesthetically pleasing finish for metal roofing systems.

This machine is ideal for producing ridge caps that match various types of roof panels, including trapezoidal, corrugated, and glazed tile sheets.

Product Specifications

| Formed Material | GI/GL, PPGI/PPGL | Thickness: 0.3-0.8mm, Width: 330mm(customized) |

| Decoiler | Hydraulic decoiler | Manual decoiler(will give you as free) |

| Main body | Roller station | 14 rows (As your requirement) |

| Diameter of shaft | 70mm solid shaft | |

| Material of rollers | 45# steel, forging with chromium plate 0.05mm, | |

| Machine body frame | 350 H Beams | |

| Dimension(L*W*H) | 5800*1000*1200 mm (customize) | |

| Weight | 3.2 Ton | |

| Cutter | Automatic | Cr12 Mov quenched treatment 58℃-62℃ |

| Power | Motor Power | 5.5 KW |

| Hydraulic system power | 4KW | |

| Voltage | 380V 50Hz 3Phase | As your requirement |

| Control system | Electric Box | Delta (As your requirement) |

| Language | English, Spanish, etc.(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| Forming Speed | 10-15m/min | The speed depends on the shape of the tile and the thickness of the material. |

Product Details

The Hydraulic cutting metal roof ridge cap roll forming machine price is designed to produce ridge caps for roofs. It is equipped with a precise roller system for shaping the metal sheets into the desired profile. The Galvanized Ridge Cap Roll Forming Machine ensures high-quality production of ridge caps for a durable and weather-resistant roofing solution.

Our Factory

We are Tianjin Haixing is a professional cold roll forming machine manufacturer.We have been focusing on this field more than 28 years.

Our equipments include R72/R101,galvateja-ternium roof roll forming machine,losacero/floor deck roll forming machine,automatic decoiler,shutter door roll forming machine,light keel roll forming machine,purlin machine,gutter roll forming machine,leveling and sliting machine,and other related construction equipment.

Looking forward to more cooperation with new and old friends .We will do our best support you !

FAQ

Tell us about your project requirements and we will figure out a solution that will meet your budget and design expectations.

Q:Are you manufacturer?

A:Yes,we are manufacturer for cold roll forming machine over 28 years.

Q: if you can accept OEM? Design and manufacture according our photo.

A: Yes, we can accept OEM,we owned expert engineer team, and use famous brand components according your demands.

Q:What's the warrany for our machine?

A: we provide 2years guarantee and provide lifetime technical support.

Q:How many workers is needed for the machine operation ?

A: One worker is engough, the machine use automatic PLC control system.

A.Yes,we owned expert export team, we can arrangement for you to your destination port or address.

A:About the pre-sale service, We provide professional solutions according your demands, such as design, technical parameter, delivery flow etc. at the same time, we can supply invitation letter for your visit our factory and know more our factory.

A: we will supply lifetime technical support and supply quick-wear parts within 2 years.

A: 25 days after deposit receipt your payment

Q: Installation and training

a.If buyers visit our factory and check the R BPR AG roof panel roll forming machine, we will teach you how to install and use the

machine, and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

c.If buyer needs our technician to go to your local factory, we could go abroad to guide you for free, but you should pay the

Transportation and accommodation expenses.

Roof & Wall Roll Forming Machine,Floor Deck Roll Forming Machine,Light Steel Keel Roll Forming Machine,CZ Purlin Roll Forming Machine,Leveling Slitting Roll Forming Machine and other related machine.

HAIXING