Purlin Forming Machine Manufacturers

Product Overview

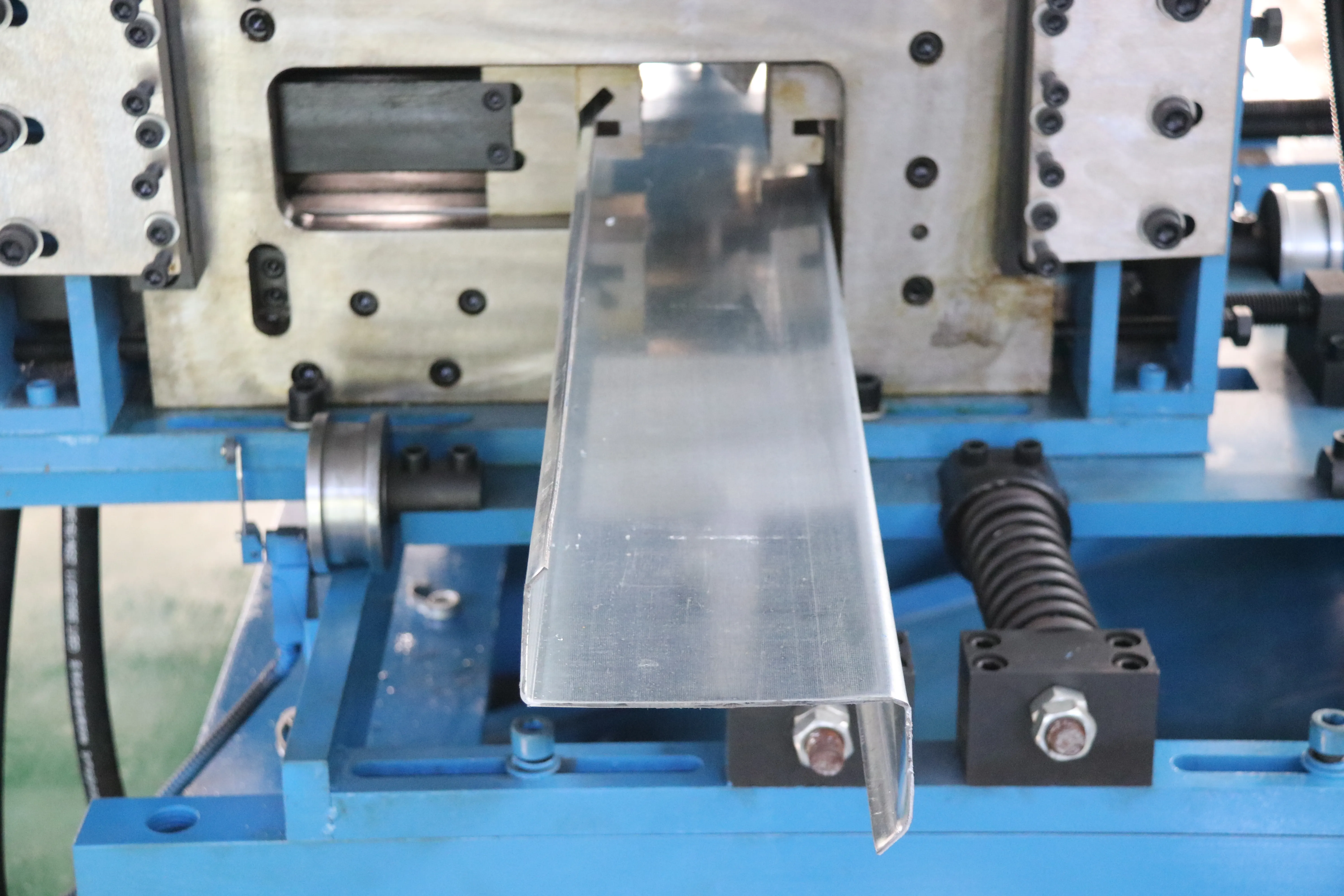

The purlin forming machine is used in the steel construction industry to produce C-shaped and Z-shaped purlins for supporting roof decking and roofing sheets.

Product Features

- The machine can produce both C-shaped and Z-shaped steel purlins in various sizes and thicknesses, with the ability to change profiles and specifications automatically.

- It comprises components such as a decoiler, punching unit, sheet levelling unit, roll forming section, and PLC control system, making it easy to operate.

- Capable of producing a variety of cross-sections and specifications, saving time and money for users.

- It can produce purlins at a fast pace and is equipped with a punching device that can punch both the web and flange side of the purlins.

- Purlin size change and CZ interchange are controlled by PLC and operate on a touch panel, taking only 1 minute.

Product Value

The purlin forming machine offers the value of versatility, efficiency, and cost savings for steel structure manufacturers.

Product Advantages

- Produces both C-shaped and Z-shaped steel purlins

- Automatic profile and specifications change

- Sturdy body frame

- Fast production pace

- Punching device for both web and flange sides

Application Scenarios

The machine is highly recommended and has great potential in the steel construction industry for producing purlins to support roof decking and roofing sheets.