Unleashing Efficiency: The Power Of A Light Steel Keel Roll Forming Machine

Are you looking to revolutionize your manufacturing process and unleash unprecedented efficiency? Look no further than the power of a light steel keel roll forming machine. In this article, we will explore how this innovative technology is transforming the industry and providing businesses with a competitive edge. From increased productivity to superior quality, the benefits of utilizing a light steel keel roll forming machine are undeniable. Join us as we delve into the potential of this game-changing equipment and discover how it can take your production capabilities to new heights.

- Introduction to Light Steel Keel Roll Forming Machines

to Light Steel Keel Roll Forming Machines

In the world of construction and manufacturing, efficiency is key. The ability to produce high-quality, precise products at a rapid pace is essential for staying competitive in today's market. This is where the light steel keel roll forming machine comes into play. This innovative piece of equipment has revolutionized the way steel keels are manufactured, offering a wide range of benefits and capabilities that make it a valuable asset for any production facility.

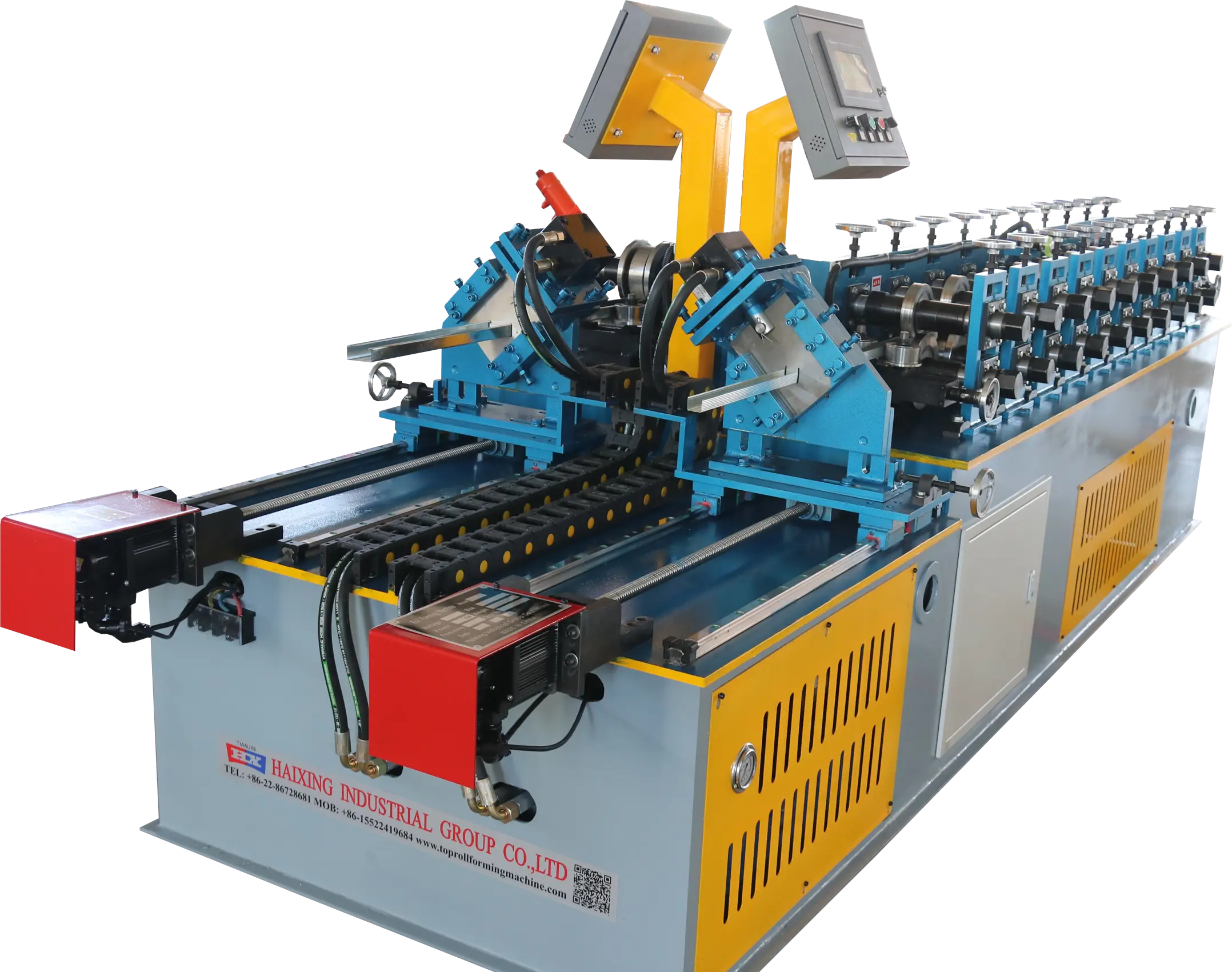

A light steel keel roll forming machine is a piece of industrial equipment designed to efficiently and accurately shape and cut steel coils into light steel keels. These keels are commonly used in construction for creating framework and support structures, making them a vital component in a wide range of building projects. What sets the light steel keel roll forming machine apart from traditional manufacturing methods is its ability to automate and streamline the production process, resulting in significant time and labor savings.

One of the key features of a light steel keel roll forming machine is its precision. Using advanced technology and precision engineering, these machines are able to produce light steel keels with consistent and exact measurements, ensuring a high level of quality and uniformity in the final product. This level of precision is crucial in the construction industry, where even the slightest deviation in measurements can lead to structural instability and safety issues.

Additionally, the speed at which a light steel keel roll forming machine operates is another major advantage. Traditional methods of manufacturing light steel keels involve numerous manual processes, often taking several steps and a significant amount of time to complete. With a roll forming machine, the entire process is automated, allowing for rapid production without sacrificing quality. This not only increases overall efficiency but also enables manufacturers to meet tight deadlines and take on larger orders with ease.

Furthermore, the versatility of a light steel keel roll forming machine cannot be overstated. These machines are capable of producing a wide range of light steel keel profiles, allowing for customization to meet specific project requirements. Whether it's for residential, commercial, or industrial applications, the flexibility of these machines makes them an ideal solution for a variety of construction needs.

In conclusion, the light steel keel roll forming machine has become an indispensable tool in modern construction and manufacturing. Its ability to streamline production, enhance precision, and increase efficiency make it a valuable asset for any company looking to stay ahead in today's competitive market. As the demand for high-quality, reliable construction materials continues to grow, the role of the light steel keel roll forming machine in shaping the future of the industry cannot be understated.

- Benefits of Using a Light Steel Keel Roll Forming Machine

The introduction of light steel keel roll forming machine has revolutionized the construction industry by providing an efficient and cost-effective means of producing high-quality building materials. In this article, we will explore the numerous benefits of using a light steel keel roll forming machine.

First and foremost, one of the most significant advantages of using a light steel keel roll forming machine is the efficiency it brings to the production process. This machine is capable of producing a large volume of light steel keels in a relatively short amount of time, significantly increasing the productivity of any construction project. This means that builders and contractors can meet tight deadlines and complete projects on schedule, ultimately saving time and money.

Furthermore, the quality of the light steel keels produced by this machine is unparalleled. The precision and accuracy of the roll forming process ensure that each keel is of uniform size and shape, with smooth edges and a flawless finish. This level of consistency is crucial in construction, as it ensures that the materials will fit together seamlessly and contribute to the overall structural integrity of the building.

In addition to efficiency and quality, the use of a light steel keel roll forming machine also offers cost-savings benefits. The machine requires minimal manual labor, reducing the need for a large workforce and the associated labor costs. Moreover, the ability to produce a large volume of light steel keels in-house eliminates the need to outsource production, saving on transportation and outsourcing costs. These cost-savings can significantly impact the overall budget of a construction project, making the use of a roll forming machine a wise investment.

Another advantage of using a light steel keel roll forming machine is its versatility. This machine is capable of producing a variety of light steel keel profiles, allowing builders and contractors to customize their building materials to suit the specific requirements of their projects. Whether it's for residential, commercial, or industrial construction, the roll forming machine can adapt to the unique needs of each application, offering a flexible and customizable solution.

Finally, the use of a light steel keel roll forming machine contributes to sustainability in construction. The roll forming process produces minimal waste, as it utilizes precise measurements to minimize material excess. Additionally, the durability and longevity of light steel keels mean that they have a lower environmental impact over time, as they require less frequent replacement and maintenance compared to other building materials.

In conclusion, the benefits of using a light steel keel roll forming machine are numerous and far-reaching. From increased efficiency and cost-savings to enhanced quality and sustainability, this machine has the power to positively impact construction projects of all sizes and scopes. As the construction industry continues to evolve, the roll forming machine stands as a testament to the innovation and advancement of modern construction technology.

- How to Improve Efficiency with a Light Steel Keel Roll Forming Machine

In the world of manufacturing and construction, efficiency is key. Companies are constantly seeking ways to improve productivity and reduce costs. One powerful tool that has emerged to help achieve these goals is the light steel keel roll forming machine. This innovative piece of equipment is revolutionizing the way that light steel keels are produced, leading to significant improvements in efficiency and cost-effectiveness.

So, how does a light steel keel roll forming machine improve efficiency? Let's take a closer look.

First and foremost, the use of a light steel keel roll forming machine streamlines the production process. Traditional methods of manufacturing light steel keels involved multiple steps and processes, often leading to a slow and labor-intensive production line. However, with the introduction of a roll forming machine, the entire process is automated, reducing the need for manual labor and significantly increasing production speed. This means that companies can produce more light steel keels in a shorter amount of time, leading to increased efficiency and, ultimately, higher profits.

Furthermore, the precision and accuracy of a light steel keel roll forming machine contribute to efficiency improvements. By using advanced technology and precise measurements, these machines are able to create light steel keels with a consistently high level of quality. This not only reduces the risk of errors and defects but also eliminates the need for rework, saving both time and money in the production process.

Another key benefit of using a light steel keel roll forming machine is the reduction of material waste. Traditional manufacturing methods often result in a significant amount of material being wasted during the production process. In contrast, a roll forming machine is able to optimize the use of materials, minimizing waste and maximizing efficiency. This not only saves money on raw materials but also contributes to a more sustainable manufacturing process.

Additionally, the flexibility of a light steel keel roll forming machine makes it a powerful tool for improving efficiency. These machines are able to produce a wide variety of light steel keel profiles, allowing companies to meet the specific needs of their customers without the need for multiple machines or complex setup processes. This flexibility not only saves time and effort but also allows companies to quickly adapt to changing market demands, improving their overall efficiency and competitiveness.

In conclusion, the use of a light steel keel roll forming machine offers a wide range of benefits that can significantly improve efficiency in the manufacturing and construction industries. By streamlining the production process, increasing precision and accuracy, reducing material waste, and providing flexibility, these machines are empowering companies to achieve higher levels of productivity and profitability. As the demand for light steel keels continues to grow, the power of a roll forming machine has become an indispensable tool for businesses looking to unleash efficiency in their operations.

- Importance of Choosing the Right Light Steel Keel Roll Forming Machine

When it comes to construction projects, choosing the right equipment is crucial to ensuring efficiency and precision. One of the most vital pieces of machinery in the construction industry is the light steel keel roll forming machine. This innovative device plays a significant role in shaping and forming light steel keels, which are essential for creating the framework of various structures.

The importance of choosing the right light steel keel roll forming machine cannot be overstated. A high-quality machine can significantly impact the efficiency and productivity of a construction project. Therefore, it is essential to consider several factors when selecting the right machine for your needs.

First and foremost, the quality of the machine is a crucial aspect to consider. A well-built and durable machine is more likely to produce consistent and accurate results, ultimately leading to a higher quality end product. When evaluating a light steel keel roll forming machine, it is important to assess the materials used in its construction, as well as the reputation of the manufacturer.

Additionally, the versatility of the machine is another essential factor to consider. A machine that can accommodate a wide range of specifications and requirements will provide greater flexibility and adaptability to different construction projects. Whether it be the size, shape, or thickness of the steel keel, a versatile machine can meet the diverse needs of various construction projects.

Furthermore, the efficiency and speed of the machine are crucial considerations. A high-performing machine can significantly reduce production time and labor costs. It is important to evaluate the production capacity and speed of the machine to ensure it is capable of meeting the demands of the project.

Moreover, the precision and accuracy of the machine cannot be overlooked. A precise machine can ensure the consistent and uniform production of steel keels, reducing the likelihood of errors and rework. The ability to produce precise and accurate results is essential for maintaining the structural integrity of the construction project.

In addition to the machine itself, it is important to consider the after-sales service and support provided by the manufacturer. A reputable manufacturer will offer comprehensive support, including training, maintenance, and spare parts availability. Choosing a machine from a manufacturer with a strong reputation for customer support can provide peace of mind and long-term reliability.

In conclusion, the power of a light steel keel roll forming machine cannot be underestimated. The right machine can unleash efficiency and productivity in construction projects, leading to higher quality results and reduced costs. By considering factors such as quality, versatility, efficiency, precision, and after-sales support, one can ensure that they are choosing the right light steel keel roll forming machine for their needs.

- Future Trends in Light Steel Keel Roll Forming Machine Technology

Light steel keel roll forming machines have revolutionized the construction industry with their efficiency and precision. As the demand for faster and more cost-effective construction methods increases, the future trends in light steel keel roll forming machine technology have become a major focus for manufacturers and builders alike.

One of the most notable trends in light steel keel roll forming machine technology is the integration of advanced automation and robotics. These machines are now equipped with sophisticated computer systems that can be programmed to perform a wide range of tasks with minimal human intervention. This not only increases the speed and accuracy of the forming process but also reduces the risk of errors and accidents. Additionally, the use of robotics allows for continuous operation, maximizing productivity and reducing downtime.

Another key trend in light steel keel roll forming machine technology is the development of more versatile and adaptable machines. Manufacturers are constantly innovating and improving their machines to accommodate a wider range of profiles and materials. This flexibility enables builders to use light steel keel roll forming machines for a variety of construction projects, from residential homes to commercial buildings. As a result, these machines are becoming essential tools for construction companies looking to streamline their operations and stay competitive in the market.

Furthermore, the future of light steel keel roll forming machine technology will also see an increased focus on sustainability and environmental responsibility. Manufacturers are increasingly utilizing eco-friendly materials and energy-efficient processes in the production of these machines. Additionally, advancements in recycling and waste management technologies are being integrated into the design of these machines, ensuring that they have a minimal impact on the environment.

On top of that, the integration of digital technology is also expected to play a significant role in the future of light steel keel roll forming machines. This includes the use of advanced software for design and production planning, as well as the incorporation of IoT (Internet of Things) technology for real-time monitoring and maintenance. These digital innovations will further enhance the efficiency and reliability of these machines, making them even more indispensable for modern construction projects.

In conclusion, the future trends in light steel keel roll forming machine technology are poised to shape the construction industry in significant ways. From advanced automation and versatility to sustainability and digital integration, these machines are continuously evolving to meet the demands of the modern construction landscape. As a result, builders and manufacturers can look forward to even greater efficiency and productivity in the years to come.

Conclusion

In conclusion, the power of a light steel keel roll forming machine cannot be understated. With 11 years of experience in the industry, we have seen firsthand how this machinery can unleash efficiency in the manufacturing process. Its ability to quickly and accurately produce light steel keels can save both time and money, while also ensuring a high-quality end product. As technology continues to advance, we can only anticipate even more powerful and efficient machines to come. Embracing these advancements will undoubtedly set us on the path to continued success in the industry.

HAIXING