Revolutionizing Construction: The Floor Deck Roll Forming Machine

Are you ready to witness a revolution in the construction industry? The floor deck roll forming machine is set to transform the way we approach building projects, offering increased efficiency, cost-effectiveness, and superior quality. In this article, we delve into the revolutionary technology behind this game-changing machine and explore the myriad benefits it brings to the construction process. Whether you're a construction professional or simply intrigued by cutting-edge advancements in the industry, this is a must-read for anyone interested in the future of construction.

Introduction to Floor Deck Roll Forming Machine Technology

The construction industry has always been evolving with new technologies and innovative solutions that aim to streamline processes and improve efficiency. In recent years, the introduction of floor deck roll forming machines has brought about a revolution in the way floors are constructed. This technology has rapidly gained popularity for its ability to produce high-quality and precisely formed floor decks in a cost-effective and efficient manner.

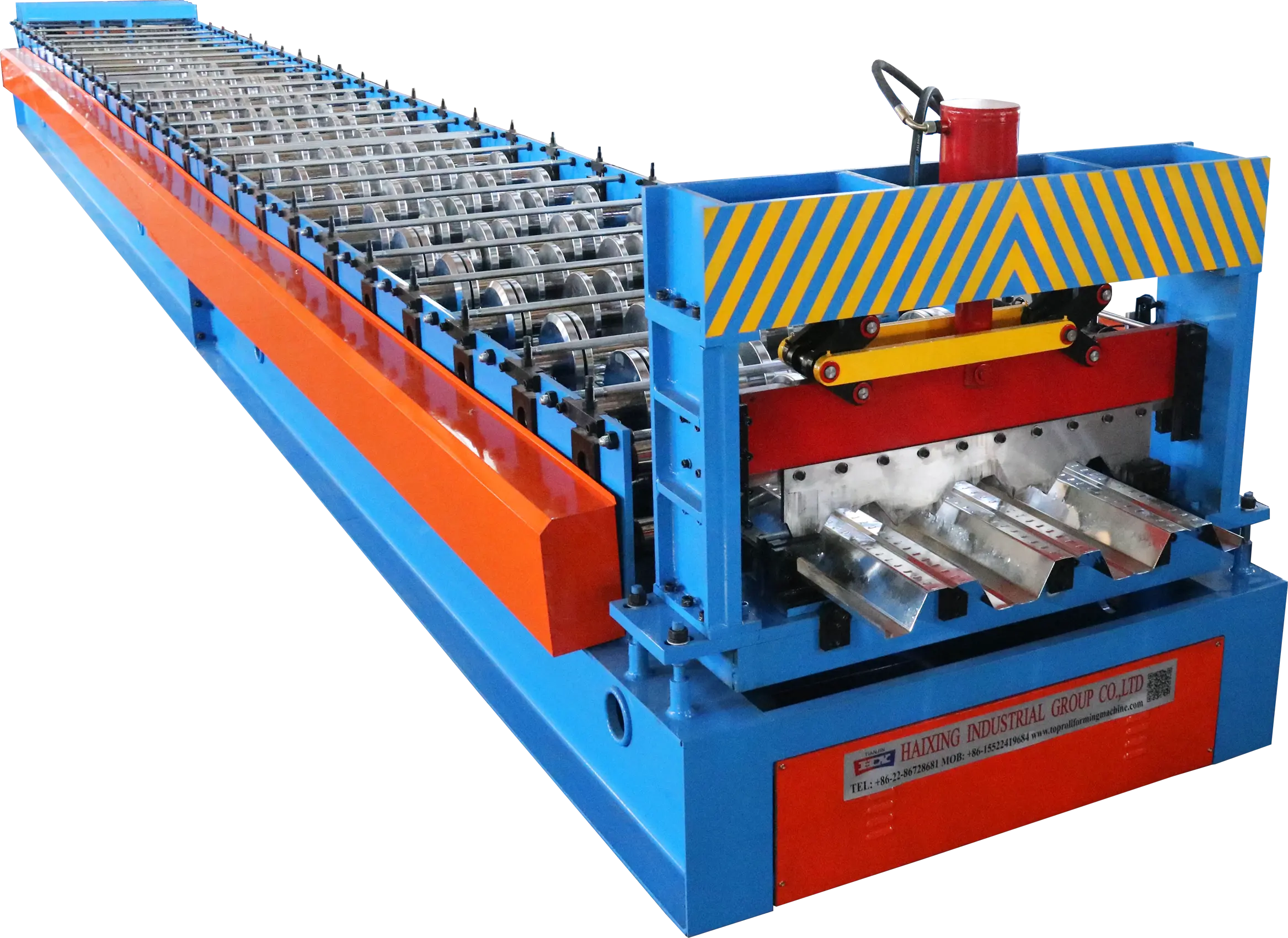

A floor deck roll forming machine is a specialized piece of equipment designed to produce metal floor decks used in construction. This machine uses a continuous bending process to shape metal coils into the desired profile, resulting in floor decks that are strong, durable, and dimensionally accurate.

One of the key features of a floor deck roll forming machine is its ability to handle a variety of materials, including steel, aluminum, and other metals commonly used in construction. This versatility allows for greater flexibility in design and construction, as different materials can be selected based on specific project requirements.

The technology behind floor deck roll forming machines is based on precision engineering and advanced control systems. These machines are equipped with automated controls that ensure consistent and precise forming of the metal coils, resulting in floor decks with uniform dimensions and minimal wastage. Additionally, the use of advanced software allows for easy customization of profiles and the ability to produce complex shapes and designs.

Furthermore, floor deck roll forming machines are designed for high-speed production, allowing for greater output in a shorter amount of time. This increased efficiency not only reduces production costs but also accelerates construction timelines, leading to overall cost and time savings for construction projects.

In addition to their production capabilities, floor deck roll forming machines also offer a range of operational benefits. These machines are designed to be user-friendly, with intuitive controls and easy maintenance. This ensures minimal downtime and maximum productivity, contributing to a seamless construction process.

The use of floor deck roll forming machines has brought about a paradigm shift in the construction industry. By streamlining the production of floor decks and offering versatile design options, these machines have revolutionized the way floors are constructed. From industrial buildings to commercial complexes and residential developments, floor deck roll forming machines have become indispensable tools for modern construction projects.

In conclusion, the introduction of floor deck roll forming machine technology has had a profound impact on the construction industry. This innovative technology has not only improved the efficiency and cost-effectiveness of floor deck production but has also contributed to the overall advancement of construction practices. As the demand for high-quality and sustainable construction solutions continues to grow, floor deck roll forming machines are poised to play a pivotal role in shaping the future of the construction industry.

Benefits and Advantages of Using a Floor Deck Roll Forming Machine

In the construction industry, innovation is key to increasing efficiency and productivity. One of the latest advancements revolutionizing construction is the floor deck roll forming machine. This machine offers numerous benefits and advantages that are changing the way floor decks are manufactured and installed. In this article, we will explore the various ways in which the floor deck roll forming machine is transforming the construction industry.

One of the primary advantages of using a floor deck roll forming machine is the efficiency it brings to the production process. Traditional methods of manufacturing floor decks can be time-consuming and labor-intensive. However, with a roll forming machine, the entire process is automated, resulting in significantly faster production times. This increased efficiency not only saves time, but also reduces labor costs, making it a cost-effective solution for construction companies.

Moreover, the precision and consistency achieved with a floor deck roll forming machine cannot be matched by manual production methods. The machine is able to produce floor decks with exact dimensions and specifications, ensuring a high level of quality and structural integrity. This level of precision is crucial in construction, as it helps to maintain the overall safety and durability of the building.

In addition to the production process, the installation of floor decks is also greatly improved with the use of a roll forming machine. The machine is able to produce floor decks in long continuous lengths, which reduces the need for on-site splicing and cutting. This not only speeds up the installation process, but also results in a smoother and more seamless finish.

Furthermore, floor deck roll forming machines are versatile and can accommodate a wide range of materials and thicknesses. This flexibility allows for the production of various types of floor decks, making it suitable for a diverse range of construction projects. Whether it’s for commercial, industrial, or residential buildings, the floor deck roll forming machine can meet the specific requirements of any project.

Another advantage of using a floor deck roll forming machine is the environmental impact. The machine produces minimal waste and scrap material, as it is able to efficiently use raw materials without generating excess offcuts. This not only reduces waste disposal costs, but also contributes to sustainable and environmentally-friendly construction practices.

Overall, the floor deck roll forming machine is transforming the construction industry by offering a more efficient, precise, and cost-effective solution for manufacturing and installing floor decks. Its ability to increase production speed, improve quality, and reduce waste makes it an indispensable tool for construction companies looking to streamline their processes and enhance their capabilities.

In conclusion, the floor deck roll forming machine is revolutionizing the way floor decks are produced and installed in the construction industry. With its numerous benefits and advantages, it has become an essential tool for increasing efficiency and productivity in construction projects. As this technology continues to evolve, it will undoubtedly play a significant role in shaping the future of construction.

The Impact of Floor Deck Roll Forming Machine on Construction Efficiency

The construction industry has seen a revolution with the introduction of the floor deck roll forming machine. This innovative piece of equipment has had a significant impact on construction efficiency, transforming the way floor decking is produced and installed. By simplifying and streamlining the process, the floor deck roll forming machine has become an essential tool for construction companies, leading to increased productivity and cost savings.

One of the key advantages of the floor deck roll forming machine is its ability to produce high-quality floor decking in a fraction of the time it takes using traditional methods. This machine uses a continuous process to roll and form metal sheets into the desired shape and size, eliminating the need for manual cutting and shaping. This not only speeds up the production process but also ensures precision and consistency in the finished product.

Furthermore, the floor deck roll forming machine is highly flexible, allowing for customization to meet specific project requirements. With adjustable parameters, such as sheet thickness, width, and length, this machine can produce a wide range of floor decking profiles, catering to the diverse needs of construction projects. This versatility minimizes the need for multiple machines or additional processes, saving both time and resources.

In addition to its production capabilities, the floor deck roll forming machine also contributes to construction efficiency through its rapid installation process. The pre-formed floor decking produced by this machine is designed to interlock seamlessly, streamlining the assembly process and reducing installation time. This not only accelerates the construction schedule but also minimizes the risk of errors during installation, leading to improved overall quality.

Beyond its immediate impact on production and installation, the floor deck roll forming machine also offers long-term benefits for construction projects. The durable and resilient nature of the pre-formed floor decking contributes to the structural integrity of the building, providing a reliable and long-lasting foundation. Additionally, the efficient use of materials and reduced waste generated by this machine align with sustainable construction practices, making it a valuable asset for environmentally-conscious projects.

Overall, the floor deck roll forming machine has revolutionized the construction industry by significantly improving efficiency in the production and installation of floor decking. Its ability to streamline processes, customize products, and enhance long-term performance has made it an indispensable tool for construction companies. As the demand for faster, more cost-effective, and sustainable construction solutions continues to grow, the floor deck roll forming machine is set to play a pivotal role in shaping the future of the industry.

Innovations and Trends in Floor Deck Roll Forming Machine Design

The construction industry is evolving at a rapid pace, with new technologies and innovations revolutionizing the way buildings are designed and constructed. One such innovation that is changing the game in construction is the floor deck roll forming machine. This machine is at the forefront of modern construction, and its design is constantly evolving to meet the demands of the industry. In this article, we will explore the latest innovations and trends in floor deck roll forming machine design, and how these advancements are shaping the future of construction.

The floor deck roll forming machine is a key piece of equipment in the construction industry, as it is used to create the floor decks that provide structural support and form the foundation of a building. As construction methods have evolved, so too has the design of these machines. One of the latest trends in floor deck roll forming machine design is the incorporation of advanced technologies, such as computerized controls and automation systems. These technologies have significantly increased the efficiency and precision of the machines, allowing for faster production and higher quality floor decks.

Another important trend in floor deck roll forming machine design is the focus on sustainability and environmental impact. With growing concerns about the environmental impact of construction, manufacturers are increasingly looking for ways to reduce the carbon footprint of their machines. This has led to the development of floor deck roll forming machines that are more energy efficient and utilize sustainable materials in their construction. Additionally, some manufacturers are exploring the use of recycled materials in the production of floor decks, further reducing the environmental impact of their machines.

In addition to technological advancements and sustainability, there is also a growing focus on flexibility and versatility in floor deck roll forming machine design. As construction projects become more complex and diverse, there is a growing demand for machines that can adapt to a wide range of floor deck designs and specifications. Manufacturers are responding to this demand by designing machines that are highly customizable and can produce a variety of different floor deck profiles. This flexibility is essential for meeting the unique needs of different construction projects and is a key factor in the continued success of floor deck roll forming machines.

In conclusion, the floor deck roll forming machine is a crucial piece of equipment in modern construction, and its design is constantly evolving to meet the demands of the industry. With advancements in technology, sustainability, and flexibility, these machines are revolutionizing the way floor decks are produced, and are shaping the future of construction. As the construction industry continues to evolve, we can expect to see further innovations and advancements in floor deck roll forming machine design, further solidifying their status as a cornerstone of modern construction.

Future Potential and Development of Floor Deck Roll Forming Machine Technology

The future potential and development of floor deck roll forming machine technology holds promise for revolutionizing the construction industry.

The floor deck roll forming machine is a critical piece of equipment that plays a vital role in the construction of buildings and structures. This machine is responsible for fabricating metal sheets into floor decks, which are essential components in modern construction. It enables the production of high-quality floor decks with precise measurements and consistent shapes, significantly reducing labor costs and production time.

In recent years, advancements in technology have led to the development of more efficient and versatile floor deck roll forming machines. These machines now boast enhanced capabilities, such as increased speed, improved accuracy, and the ability to produce a wider range of floor deck profiles. These developments have not only streamlined the construction process but have also opened up new possibilities for the integration of floor deck systems in various types of buildings, from residential to commercial projects.

One of the most significant areas of future potential for floor deck roll forming machine technology lies in its adaptability to sustainable construction practices. As the construction industry continues to strive for eco-friendly solutions, floor deck roll forming machines have the potential to facilitate the use of recycled materials in the production of floor decks. This not only reduces the environmental impact of construction but also aligns with the growing demand for sustainable building materials.

Furthermore, the development of floor deck roll forming machine technology has the potential to improve the overall safety and durability of buildings. By utilizing advanced materials and manufacturing techniques, floor deck systems can be engineered to withstand a wider range of environmental conditions, from extreme temperatures to seismic events. This not only enhances the longevity of buildings but also contributes to the safety and well-being of occupants.

Another area of future development for floor deck roll forming machines lies in their integration with digital technology. Advancements in automation and data analysis have the potential to further enhance the efficiency and accuracy of these machines, leading to increased productivity and reduced material waste. Additionally, the integration of digital technology can enable real-time monitoring and maintenance of floor deck roll forming machines, further improving their reliability and performance.

In conclusion, the future potential and development of floor deck roll forming machine technology hold great promise for revolutionizing the construction industry. With ongoing advancements in efficiency, sustainability, safety, and digital integration, these machines are poised to play a pivotal role in shaping the future of construction and building design. As technology continues to evolve, the impact of floor deck roll forming machines on the construction industry is sure to be transformative.

Conclusion

In conclusion, the floor deck roll forming machine has revolutionized the construction industry in more ways than one. With 11 years of experience in the industry, our company has seen firsthand the incredible impact that this innovative machine has had on construction projects. From its ability to streamline the construction process to its cost-effectiveness and durability, the floor deck roll forming machine has certainly changed the game. As we look towards the future, we are excited to see how this technology will continue to shape the construction industry and drive even more efficiency and innovation in the years to come.

HAIXING